Energy

Wind/Solar

Hydro

Nuclear

Pipelines

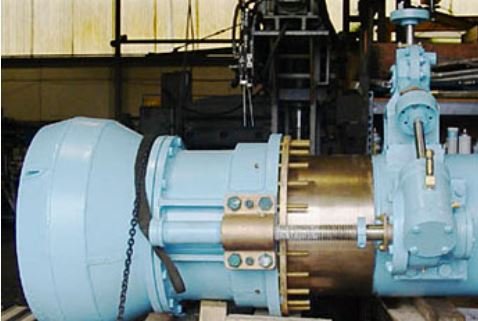

MI is able to deliver critical components on time, with exacting quality standards. We are able to repair large gear boxes, provide manufacturing of prototypes and replacement of original equipment.

If there is a need for large machining, prototype machining, replacement of broken parts, creation of assembly line spares or new equipment design, give the experts at Machinists a call for reliable handling of your project.